Carbon Fiber Longboard

A custom Carbon Fiber Longboard I created at SCAD

Process

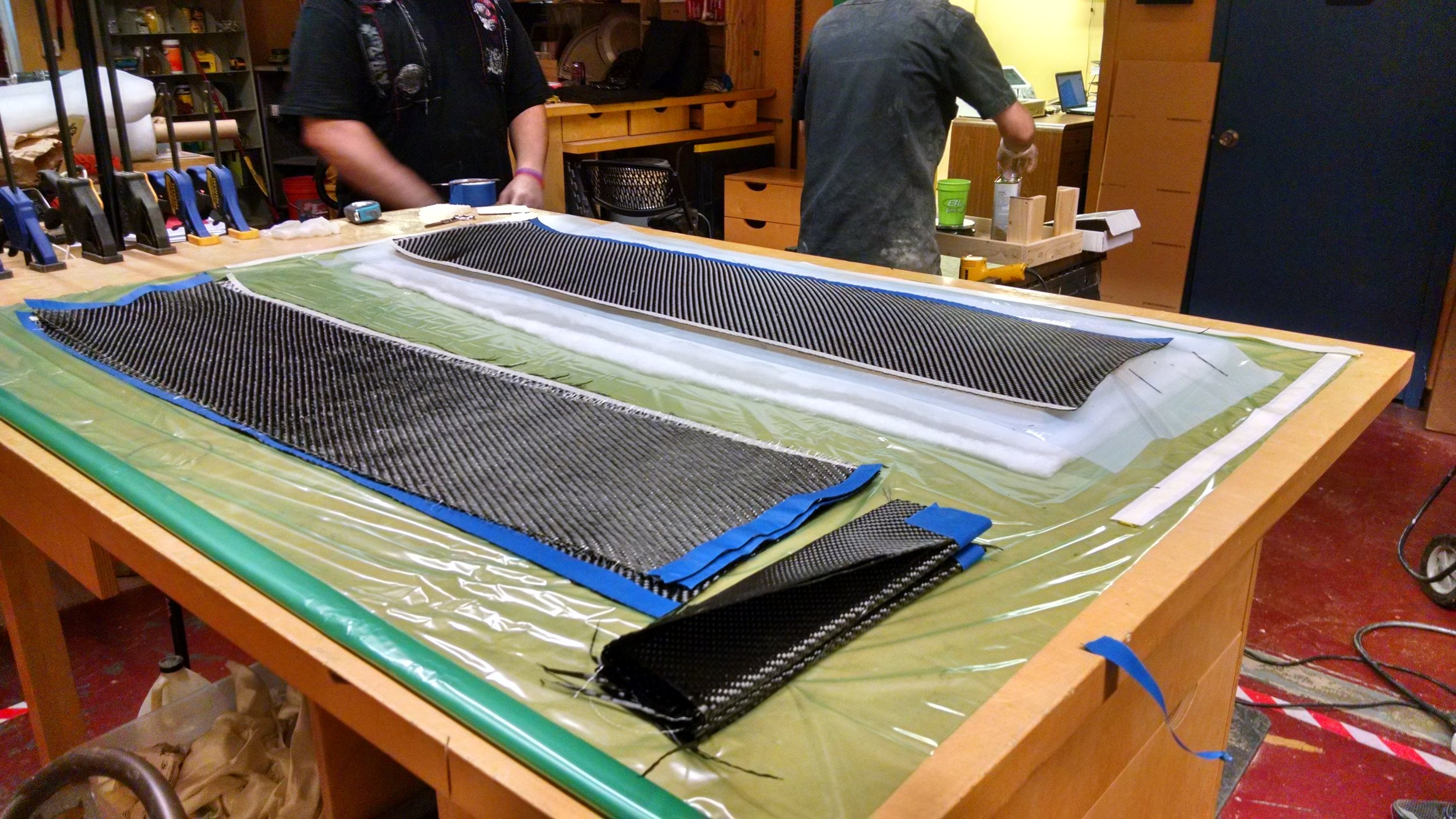

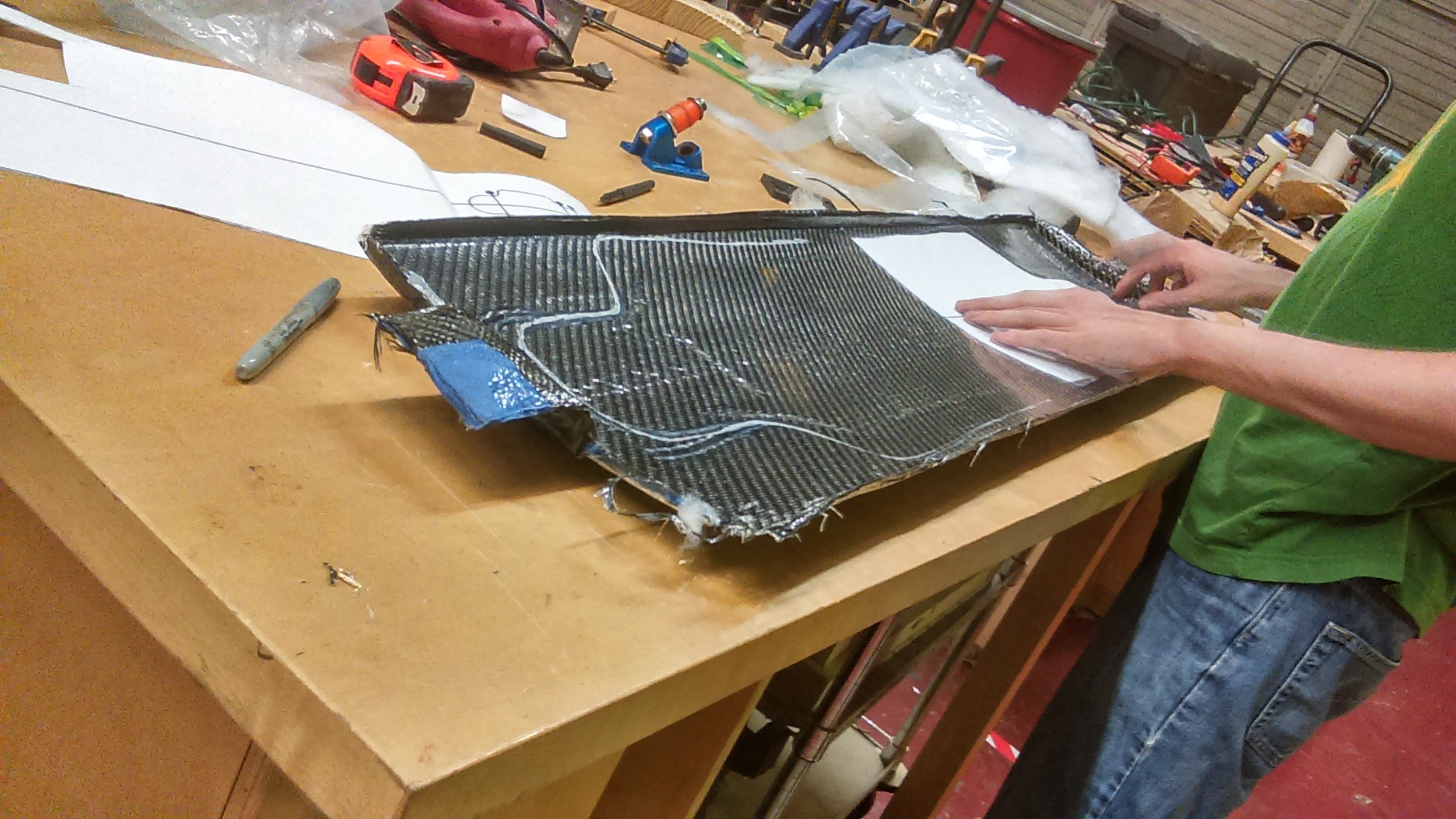

To create this longboard, I started with a CNC mold to create the desired concave of the board. I used a high-density foam that would not dissolve when coming in contact with resin as the core of the board to keep it lightweight. Using two different weave patterns of carbon fiber for the inner and outer layers of the board I was able to keep cost down and while maintaining a clean look. After the vacuum bag process, I cut the desired shape of the board out with a jig saw.

About

This was one of my first projects at SCAD. The motivation behind this was to test the skills I had learned in my first two quarters at SCAD. The goal was to create a new, strong, and lightweight longboard that I could use to get around Savannah and to my classes.